Features and benefits of the device:

The mentioned device reduces about 70% of waste disposal costs in the hospital.

• No need for cellophane and fireproof bags

• No need to separate all types of infectious waste and use special packaging

• Volume reduction of 80% and weight reduction of about 50% at the end of the work

• Garbage is sterilized up to 6Log10.

• Low cost of repair and maintenance of the safety device, unlike internal shredders

• Use of safe pneumatic systems and quick evacuation and higher security

• Useful volume of the device for loading 1000 liters or equivalent to 200 to 250 kg

• The working time of the device including loading and a full cycle and unloading is 35 minutes and the ability to work 35 cycles in 24 hours.

• There is no wastewater.

• It does not require biological wastewater treatment.

• Steam and polluted air do not come out of the device.

• It does not require vacuum and biological air purification.

• The used steam is returned to the steam generator in the form of hot distilled water. A lot of energy is recovered

Boiler energy consumption is reduced by 50%. The life of the steam generator also increases and as a result the water consumption

In the sterile cycle, it is about zero.

• The shredder of these devices has no problem with dialysis filters, oxygenators, etc

• At the moment of starting the machine, the crushing and sterilization are done at the same time, so the speed

Sterility is higher in these devices, on the other hand, the grinding process is done at 110 degrees Celsius

It is done that at this temperature all plastic materials have become liquid. In these conditions of action

Shredding will be done with the least power consumption.

• All tests and biological vials are placed in the outlet and the blindest point in the device

• Packaging with normal and cheap bags is allowed

• Use of inverter to control the engine and gearbox and lower cost

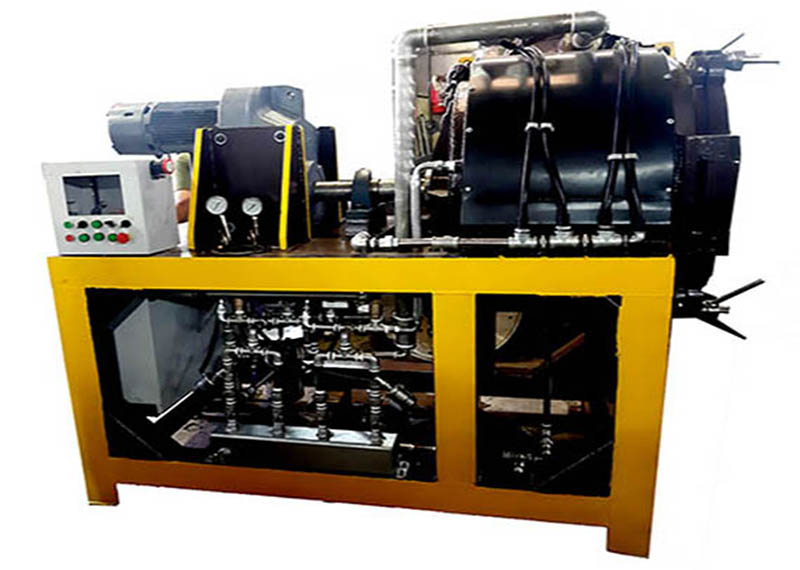

• Rotating system with a motor and two stirring and crushing arms that rotates slowly inside the tank.

• Fully automatic control panel by plc and touch-sensitive monitors with hard record system

Hardware (printer) and software (flash) and the ability to connect to the hospital’s central network system and monitor

In the central server and the sound broadcasting system and the recording and display system of all events and alarms and the system

Temperature and pressure control and display

• The existence of a steam trap (Trap) for automatic condensation

• Thermal insulation of tanks to reduce energy loss

• The presence of a suspension system in the shaft to prevent leakage in the packing

• Existence of an accurate mechanical seal system, no need to replace packing and O-rings around the door

• Presence of pressure switch and safety valve in order to increase safety

• Simple repair and maintenance system and no need for a professional user

• Existence of a sterilized steam evacuation system and a system to eliminate the bad smell of garbage

• Drying inside the tank, after the waste sterilization cycle

• Control and display of temperature and pressure of the steam tank and waste tank

• Garbage does not burn and does not have waste-burning pollutants.

• It dehydrates and dries the waste and lightens it to about 50% of the original weight